How We Found Profitability In An Ultra-Specific

Niche

Hello! What's your background, and what are you working on?

Hey! My name is Yonatan. I'm a full stack developer and an internet entrepreneur. I was working for quite a few tech companies as a developer and a team leader before I realized what I do best is starting things.

Since March I've been working together with my two co-founders (Assaf and Adar) on a shiny new company called Jiga. We help 3D printing, computer numerical control (CNC) machining, and sheet metal customers connect with trusted manufacturers while removing communication frictions.

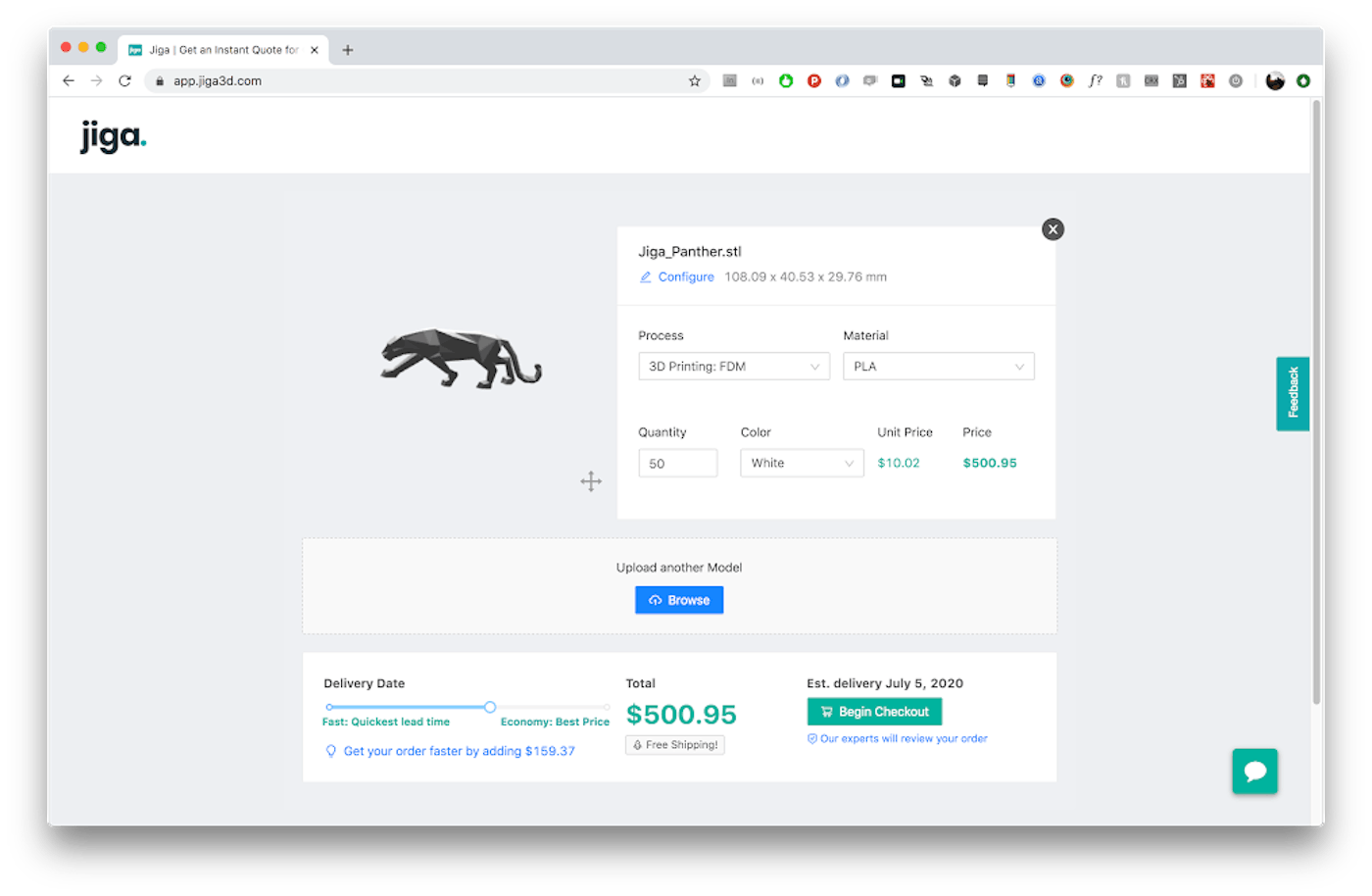

We developed a really cool pricing algorithm that can calculate the price of printing and/or machining a 3D model within seconds. This alone is helping a lot of consumers to get an instant price quote and compare different manufacturers, technologies, and materials. We also have a wide network of 3D printing and CNC machining manufacturers around the world, thanks to my co-founder’s experience in this field.

Today we are making roughly $3K MRR from about 10 orders per month. We have some returning users, which is the metric that’s most important for us.

What motivated you to get started with Jiga?

My co-founder was managing a few 3D printing companies in Israel in previous roles when he came up with a completely different startup idea. While he was working on the other startup idea, people called him nonstop, asking if he knows where they can print or manufacture their 3D models. It took him maybe 10 to 15 calls like that to understand that this can be scaled into a business.

In order to validate this, Assaf and Adar bought the domain jiga3.com and added a simple form with an option to upload a 3D model that said: "Instant quotes for manufacturing your 3D models." Of course this was all manual. Assaf was behind the scenes answering emails to anyone who uploaded a model with a price quote. In my opinion, this one is a brilliant initial product validation.

At this point I joined the team, building the platform and the algo behind it, so we could scale our business.

We onboarded real manufacturers to the system, they provided us their pricing model, and we adjusted it so our system could output a quick price quote based on the manufacturer specs. Today, every quote requested on our web app triggers a query for tens of manufacturers to find the best fit (in terms of price, quality or lead time) for the customer.

What went into building the initial product?

We worked on the initial MVP for about one and a half months, and since then we soft-launched to keep validating our assumptions and get feedback from users. We got a lot of very valuable feedback from users and customers, which led us to another phase of focusing on fixing our infrastructure and making new assumptions.

We're all second-time entrepreneurs, which probably helps us keep working in a relaxed and fun atmosphere while still working fast and focusing on relevant features and tasks.

One thing that had a major influence on us is the pandemic outbreak. It made us stay at home and focus on building our product instead of, for instance, going to the beach. (And when you live five minutes walk from the beach, that's a real temptation, believe me!)

What's your tech stack?

We build the app with React/Next.JS, which saves tons of server costs when you can serve this on a static site platform like Vercel.

Our back end is written in NodeJS for the most of it, with some fancy 3D-related modules written in Python. For databases we have MongoDB and a bunch of heavily manipulated JSONs served on S3.

Some of our back-end services are served on Render, which in my opinion is the friendly, cheap, and easy version of Heroku.

How have you attracted users and grown Jiga?

At the moment, we're mainly focusing on cold calls and emails to validate and refine our product. Because we take so few orders monthly, it's important that we learn and refine our methods with each one.

Another huge growth area for us is community creation. We're building a community of mechanical engineers, an area that's really growing right now in Israel.

We do have some SEO tricks though! We have a lot of keywords we can focus on, which you can see on our website, and a lot of them are very niche, which is helpful in SEO.

What's your business model, and how have you grown your revenue?

At the moment our business model is taking a margin from each order that goes through the platform. And that margin really varies depending on the scope and type of the order.

For example, we prefer to not take really big orders, because we don't have the cash to insure it yet. When we see a big order coming in, we take care of the details and then forward the rest to one of our trusted manufacturers. This way we build better relationships for the next steps.

What are your goals for the future?

Our next big milestone is to reach $20K MRR so we can leave our consulting businesses and pay ourselves a small salary. Our long-term goal is to be the top online platform in the on-demand manufacturing field.

In every step of the way we see how this market is inefficient and could use our software to improve the work of tens of thousands of engineers and procurement managers around the world, while providing and organizing work for thousands of trusted CNC machining, 3D printing, and sheet metal manufacturers.

We'd like to be in a position such that engineers around the world would think about Jiga when they want to produce a custom part for prototyping or when they plan a big machine. For example, think about medical device startups who need to be very agile with their manufacturing. Instead of manually sourcing for vendors, making mistakes, negotiating and comparing prices, they can order custom parts instantly through a trusted online platform.

What are the biggest challenges you've faced and obstacles you've overcome?

One of the biggest challenges for us was initially reaching potential customers, since this is a fairly specific niche. And then we needed to make them trust us that we will deliver. We had to hack it somehow.

It helps to have domain expertise in these situations. Once you know people in this field you have the first bunch of potential customers to talk to, and you can get a lot of feedback early on.

Another major challenge we have to face is building the algorithm to take into account many important professional factors that we don’t always know. For that, we get help from the manufacturers that signed up on our platform. I think that understanding our unique USP and doubling down on adoption is something that we should focus on. When we lose focus on the key metrics like returning customers we always regretted it afterwards.

Have you found anything particularly helpful or advantageous?

There’s one thing that I’d love to mention. As an early-stage startup that started during the pandemic, we noticed that it’s easier for us to convince people to try new things and change old habits. This is crucial for startups to succeed, and I’m not sure this is obvious for everyone.

This especially impacted us because almost everything in our field, from 3D printing, to CNC machining, to sheet metal, all deal with the supply chain. We're hoping we can gain more traction at a time when people are really more open to innovation.

Another powerful thing is the people around us. The people we talked with were very nice and were willing to help when we just started. They helped us so much in refining our idea! Without their feedback we wouldn’t be able to advance the way we did.

What's your advice for indie hackers who are just starting out?

Just go and f-ing do it. Every other day I see wantrepreneurs talking about their idea but actually do nothing about it. Your idea isn't worth a penny if you don’t spend time and sweat doing something about it.

A common mistake I see people do all the time is trying to create something big from the start with a lot of assumptions and without proper validation. Do you know what the best validation metrics are? Profit and returning customers.

If you can make even a tiny bit of money, and make people happy enough, they’ll come again, even from a very simple transaction. You've got something in hand. Now go and scale it. Build something big, but in baby steps, and always validate every single move you do.

Where can we go to learn more?

You can check out our website at jiag3d.com and please follow our progress on Indie Hackers and on LinkedIn. We often share our progress transparently.

Feel free to comment here or to reach out personally, we’ll be very happy to answer any questions you have. Especially ones that relate to starting out — bootstrapping businesses, marketing at early stages and building the product early on.

And obviously, if you know mechanical engineers or manufacturers that would be interested to hear about Jiga, let us know!